Global Automotive Pillar Market Outlook

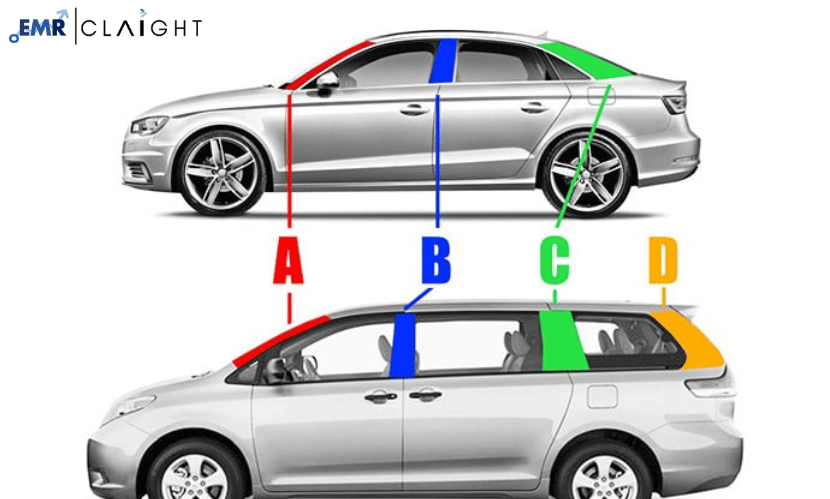

The global automotive pillar market reached a value of approximately USD 6.88 billion in 2023. The market is projected to grow at a compound annual growth rate (CAGR) of 4.0% between 2024 and 2032, reaching an estimated value of USD 9.78 billion by 2032. Automotive pillars are integral structural components in vehicles that provide support and enhance the overall safety and stability of the vehicle. These pillars are categorized into several types, including A-pillars, B-pillars, C-pillars, and D-pillars, each playing a specific role in the vehicle’s structure.

The steady growth of the automotive pillar market can be attributed to several factors, including the rising demand for automobiles globally, advancements in automotive safety technologies, and increasing emphasis on vehicle design and aesthetics. This article explores the key factors driving the growth of the automotive pillar market, emerging trends, challenges, and the future outlook of this vital segment of the automotive industry.

Key Drivers of the Global Automotive Pillar Market

1. Growing Automotive Industry

One of the primary drivers of the automotive pillar market is the global expansion of the automotive industry. The increasing demand for passenger vehicles and commercial vehicles in both developed and developing regions is boosting the market for automotive pillars. Emerging economies in Asia-Pacific, Latin America, and Africa are experiencing a surge in vehicle ownership due to rising disposable incomes, urbanization, and improved road infrastructure. This growth in the automotive industry is leading to increased production and sales of vehicles, which, in turn, is driving demand for automotive components, including pillars.

In addition, the recovery of the automotive industry following the COVID-19 pandemic has contributed to the market’s growth. As economies reopened and consumer confidence returned, the demand for new vehicles increased, further fueling the need for automotive pillars.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/automotive-pillar-market/requestsample

2. Advancements in Automotive Safety Technologies

Automotive safety is a critical factor that influences vehicle design and production. In recent years, there has been a growing focus on improving the safety features of vehicles to reduce the risk of accidents and injuries. Automotive pillars play a crucial role in enhancing the safety of vehicles by providing structural support, especially during collisions. These pillars are designed to absorb impact forces and maintain the integrity of the passenger compartment, thereby protecting the occupants of the vehicle.

Advancements in materials and manufacturing technologies have enabled the development of lightweight yet strong automotive pillars that offer improved crash protection. For example, the use of high-strength steel, aluminum, and composite materials in pillar construction has enhanced their performance in crash tests, making vehicles safer for consumers. Moreover, the integration of advanced safety systems such as side-impact airbags and curtain airbags in automotive pillars has further bolstered their importance in vehicle safety.

As regulatory authorities worldwide continue to implement stringent safety standards for vehicles, automakers are investing in research and development to improve the safety features of their vehicles. This trend is expected to drive the demand for advanced automotive pillars that meet or exceed safety requirements.

3. Increasing Focus on Vehicle Design and Aesthetics

In addition to safety, vehicle design and aesthetics have become important factors that influence consumer preferences. Automakers are increasingly focusing on creating visually appealing vehicles that offer a balance of style, comfort, and functionality. Automotive pillars, particularly A-pillars and C-pillars, are key components that contribute to the overall design and appearance of a vehicle.

For example, slim A-pillars are favored for providing better visibility for drivers while enhancing the sleek and modern look of the vehicle. Similarly, well-designed C-pillars can improve the aerodynamic performance of the vehicle and contribute to its overall aesthetics. Automakers are experimenting with new designs, materials, and manufacturing techniques to create automotive pillars that not only improve safety but also add to the visual appeal of their vehicles.

As consumer preferences continue to evolve, automakers are likely to place greater emphasis on design and aesthetics, driving demand for innovative automotive pillars that combine form and function.

Emerging Trends in the Global Automotive Pillar Market

1. Lightweight Materials and Sustainability

The automotive industry is undergoing a transformation as automakers strive to reduce the environmental impact of their vehicles. One of the key trends shaping the industry is the shift toward lightweight materials and sustainable manufacturing practices. Lightweight materials such as aluminum, carbon fiber, and advanced composites are increasingly being used in the production of automotive pillars to reduce the overall weight of vehicles. This helps improve fuel efficiency and reduce carbon emissions, aligning with global efforts to combat climate change.

In addition to reducing weight, sustainable manufacturing practices are gaining traction in the automotive industry. Automakers are exploring ways to minimize waste, reduce energy consumption, and use recyclable materials in the production of automotive components, including pillars. For example, some manufacturers are incorporating recycled materials into their pillar designs, contributing to a more sustainable supply chain.

As environmental regulations become more stringent and consumers become more environmentally conscious, the demand for lightweight and sustainable automotive pillars is expected to grow.

2. Electric Vehicles (EVs) and Autonomous Vehicles (AVs)

The rise of electric vehicles (EVs) and autonomous vehicles (AVs) is another significant trend that is reshaping the automotive industry. As automakers shift their focus toward electrification and autonomous driving technologies, the design and construction of vehicles are evolving to accommodate new powertrains and sensor systems.

In electric vehicles, the placement of the battery pack and the need for optimal weight distribution are influencing the design of automotive pillars. Lightweight materials and innovative designs are being used to ensure that EVs meet safety standards while maximizing efficiency. Additionally, the need for enhanced visibility and sensor integration in autonomous vehicles is driving demand for new pillar designs that support advanced driver assistance systems (ADAS) and autonomous driving technologies.

As the adoption of EVs and AVs accelerates, the automotive pillar market is expected to see increased demand for specialized components that cater to the unique requirements of these vehicles.

3. Advanced Manufacturing Technologies

The adoption of advanced manufacturing technologies such as additive manufacturing (3D printing), automation, and robotics is transforming the production of automotive components, including pillars. These technologies offer several benefits, including increased precision, reduced production time, and lower costs. Additive manufacturing, for example, allows for the production of complex pillar designs that would be difficult or impossible to achieve using traditional manufacturing methods.

Automation and robotics are also being used to streamline the production process, improve quality control, and enhance efficiency. As automakers continue to invest in advanced manufacturing technologies, the automotive pillar market is expected to benefit from increased innovation and improved production capabilities.

Read Full Report with Table of Contents@ https://www.expertmarketresearch.com/reports/automotive-pillar-market

Challenges Facing the Global Automotive Pillar Market

1. Supply Chain Disruptions

The automotive industry has faced significant supply chain disruptions in recent years, particularly during the COVID-19 pandemic. The global shortage of semiconductors, rising raw material costs, and logistical challenges have impacted the production and delivery of automotive components, including pillars. While the industry is gradually recovering, supply chain disruptions remain a challenge that could affect the growth of the automotive pillar market.

To mitigate these risks, automakers and suppliers are exploring strategies such as diversifying their supply chains, building inventory buffers, and investing in local manufacturing capabilities. These efforts are aimed at reducing the impact of future disruptions and ensuring a stable supply of critical components.

2. Fluctuating Raw Material Prices

The cost of raw materials used in the production of automotive pillars, such as steel, aluminum, and composites, is subject to fluctuations due to factors such as changes in global demand, trade policies, and market volatility. Rising raw material prices can increase the production costs of automotive pillars, affecting the profitability of manufacturers and potentially leading to higher prices for consumers.

To address this challenge, manufacturers are focusing on optimizing their supply chains, improving operational efficiency, and exploring alternative materials that offer cost savings without compromising on quality or performance.

3. Stringent Regulatory Requirements

The automotive industry is subject to stringent regulatory requirements related to safety, emissions, and sustainability. These regulations vary by region and are continuously evolving to address new challenges and emerging technologies. For example, safety regulations require that vehicles meet specific crashworthiness standards, which directly impact the design and construction of automotive pillars.

Meeting these regulatory requirements can be challenging for automakers and component manufacturers, as they must invest in research and development to ensure compliance. Additionally, navigating the complex regulatory landscape across different regions can be time-consuming and costly.

Future Outlook of the Global Automotive Pillar Market

The global automotive pillar market is expected to continue its growth trajectory in the coming years, driven by factors such as the expansion of the automotive industry, advancements in safety technologies, and the increasing focus on sustainability. As automakers innovate and adapt to changing consumer preferences and regulatory requirements, the demand for advanced automotive pillars is expected to rise.

The growing adoption of electric vehicles and autonomous vehicles will also create new opportunities for the automotive pillar market. Specialized pillar designs that cater to the unique needs of these vehicles, such as lightweight materials and sensor integration, will become increasingly important as the industry transitions toward electrification and automation.

In addition, the continued focus on sustainability and the use of advanced manufacturing technologies will shape the future of the automotive pillar market. Manufacturers that prioritize innovation, sustainability, and operational efficiency will be well-positioned to capitalize on the growth opportunities in this dynamic market.

Read More Reports:

Methyl Isobutyl Ketone Market: https://www.expertmarketresearch.com/reports/methyl-isobutyl-ketone-market

Photovoltaic Materials Market: https://www.expertmarketresearch.com/reports/photovoltaic-materials-market

Thermosetting Plastics Market: https://www.expertmarketresearch.com/reports/thermosetting-plastics-market

Media Contact:

Company Name: Claight Corporation

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/